Solutions

Our Solutions & Benefits

- Provide whole line for your carbonated soft drinks factory.

- We can help you customize the production line for filling carbonated beverages into various bottle containers such as glass bottles, cans, and plastic bottles

- Carbonated soft drinks production line production capacity up to 36000BPH.

- Experienced team of experts at your service.

- Use high quality parts and raw materials to produce bottle water machines.

How can we help?

Cola, Sprite, Soda, sparkling water, cocktail, flavored water…the variety of carbonated beverage is ever changing. New trend, new products and new packaging are emerging continuously.

For carbonated filling machines, how to rise up the filling temperature to reduce energy consumption? How to reduce foaming? How to keep accurate filling? How to avoid the residuals in the neck? How to preserve the CO2…it is not an easy task to handle all these challenges. However, no matter what products, LIDLI has done many carbonated beverage solution projects, we know how to avoid problems.

Meanwhile, LIDLI filling machine can realize multiple functions in one equipment. One machine can do water, carbonated drinks and hot filling products.

What is Included

Before the water is filled into the empty bottle, the raw water needs to be filtered and sterilized by the water treatment system to meet the relevant standards in order to be safe in production. Bottled drinking water can be classified into two categories, mineral water and pure water, which require different water treatment processes. The water treatment equipment for the production of mineral water uses Ultrafiltration technology to filter out the impurities and harmful substances in the water and retain the beneficial minerals in the raw water to the maximum extent, so the mineral water will have a special taste. The preparation of purified water requires osmosis membrane filtration technology to reduce TDS and electrical conductivity to the range of international standards, so pure water is colorless and tasteless.

Before the water is filled into the empty bottle, the raw water needs to be filtered and sterilized by the water treatment system to meet the relevant standards in order to be safe in production. Bottled drinking water can be classified into two categories, mineral water and pure water, which require different water treatment processes. The water treatment equipment for the production of mineral water uses Ultrafiltration technology to filter out the impurities and harmful substances in the water and retain the beneficial minerals in the raw water to the maximum extent, so the mineral water will have a special taste. The preparation of purified water requires osmosis membrane filtration technology to reduce TDS and electrical conductivity to the range of international standards, so pure water is colorless and tasteless.

Used to produce PET empty bottles for water bottling factories, there are two categories: semi-automatic bottle blowing machine and full-automatic PET blow molding machine. Automatic PET bottle blowing machine is the mainstream choice in the market at present, it saves energy consumption, improves production efficiency, and can be connected to water bottling machine through air conveyors.

At present, we can provide a series of bottle blowing equipment for you to choose, from small bottles to large bottles, from low speed to high speed, Lidli has rich experience to deal with your demand.

Wide range of uses - The system can handle a wide range of products such as carbonated drinks, juice drinks, etc.

Easy power adjustment - easy adjustment of mixing ratio without having to replace parts.

Structural Hygiene - All parts in contact with fluids are of high quality stainless steel, all tanks are equipped with CIP ball for easy cleaning.

Accurate mixing accuracy - product mixing accuracy G ≤ 2%

The machine is mainly used for filling carbonated drink. It combines rinsing and filling and capping as one automatic body suitable for PET or other plastic bottles. The iso-pressure (iso-barometric) filling technology is adopted enabling it to fill more efficiently and more stably with more output than the machine of the same level from others.

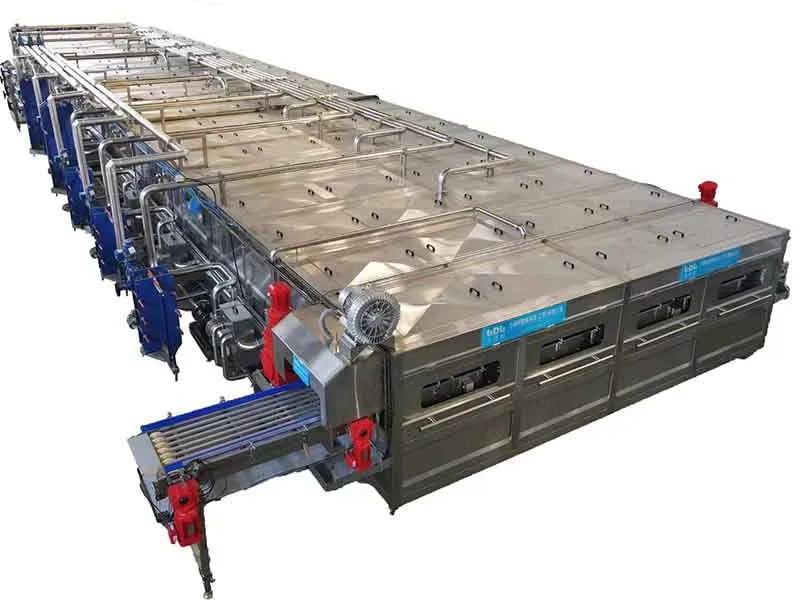

Mainly for cooling and sterilization

The main parts of the machine are made of stainless steel, the top is designed to be openable for easy maintenance and observation

Nozzles are manufactured using U.S. technology and spray water evenly

Conveyor belt adopts Rexnor technology, flat surface with small wear

Smooth and reliable operation with low energy consumption

The function of the labeling machine is to attach the label to the bottle, and an excellent water bottle label design will bring unexpected benefits to bottled water brands, so more and more water bottling plants begin to pay attention to the design and type selection of labels.

For bottled water factories, there are usually three types of labels to choose from: PVC shrink sleeve label, self-adhesive label, and OPP hot melt gule label. These three labels require three different labeling machines, so before choosing, you can refer to the mainstream products in the market for evaluation.

Individual bottled water is not suitable for long-distance transportation and storage, so bottled water needs to be packed according to a certain format. At present, the mainstream are PE shrink film packaging and carton packaging, corresponding to two different packaging machineries. Most water bottling plants will choose PE shrink film packaging machine because the cost of packaging material (PE film) is relatively low. A small number of high-end positioning of bottled water or glass bottle water will choose carton packaging machine.

The transmission of PET empty bottles usually adopts air conveyor, which is efficient and fast. The air conveyor can connect the fully automatic bottle blowing machine and the water bottling machine, or connect the bottle unscrambler and the water bottling machine. Reduce the manual handling workload and reduce the use area of the warehouse.

After completing the water bottling work, buffering conveyor is needed to connect all the downstream packaging equipment, such as labeling machine, packaging machine, inkjet printer, palletizer, etc.

The layout of buffering conveyor is designed according to the actual situation of the customer factory, and the reasonable design of buffering conveyor can improve the efficiency of the whole production line.