Blow Molding System

Mineral Water Plastic Bottle Blow Molding Machine

Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc. Beverage bottle, cosmetic bottle, medicine bottle, jar etc.

Technical Data

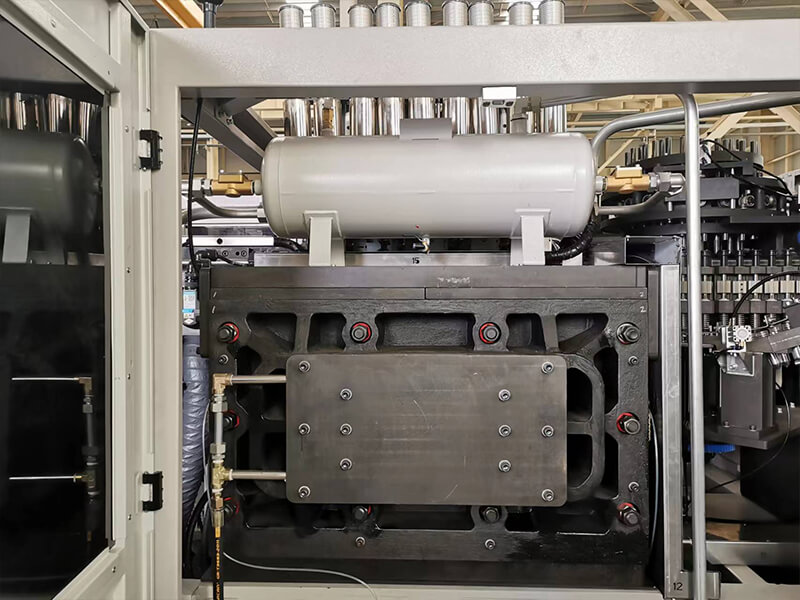

Linear Automatic PET Blow Molding Machine is an economical model self-developed by LiDLi technical team, with features economic, fast, convenient. It can make different kinds of PET packages for water, edible oil, juice, wine, cosmetics, etc. It can make max. 2Litre bottle.

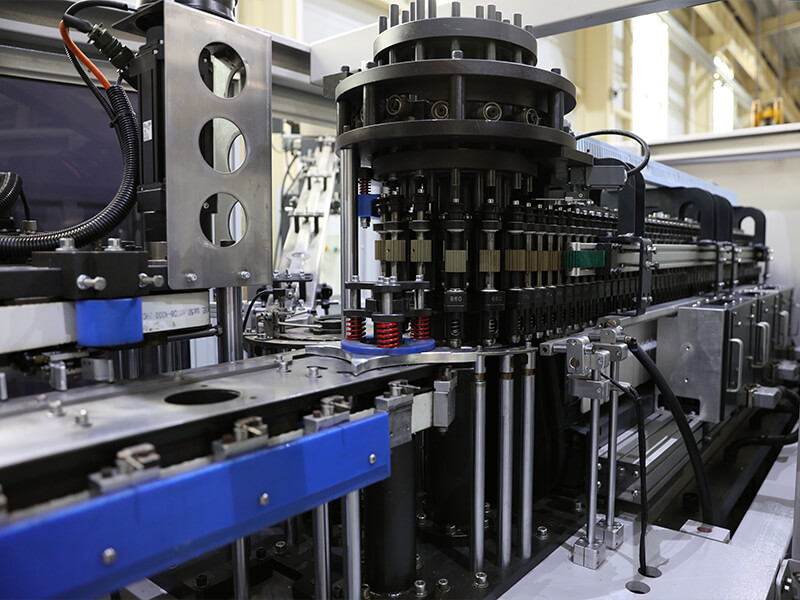

- Upgrade to Servo Motor Drive:

a.Preform Feeding System: servo motor partitioning effectively solves the problem of wear and deformation.

b.Preform Transfer System: PET preform horizontal movements are driven by Servo Motor. Make preforms 4pcs as one unit, overall simplified stepping motion, achieve high-speed positioning and smooth motion. to complete one step cycle, the Servo Motor drive gear rotates only one-third of a turn. Speed of preform moving is 2 times of Cylinder Driven way. - Mold fixed by drawer design, mold changeover can be easily done in a half-hour.

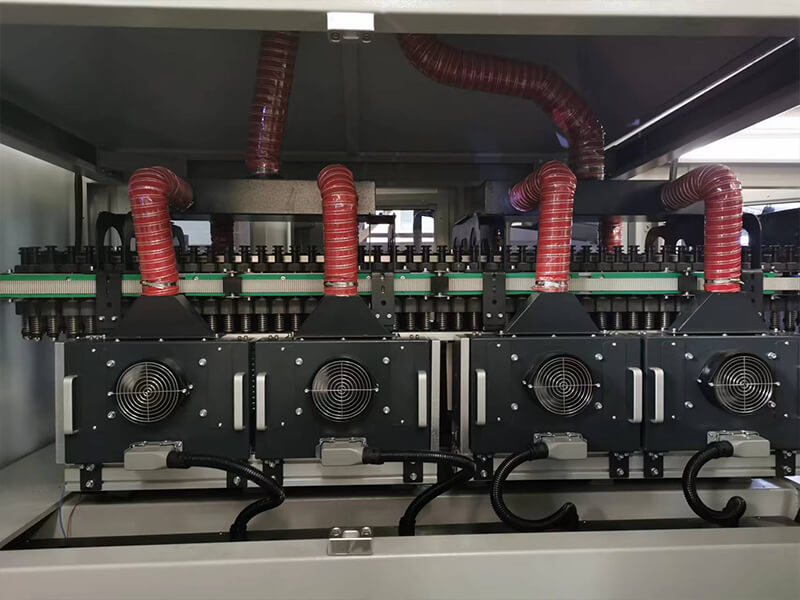

- Efficiency Constant Temperature Oven:

a.Use the most advanced high-frequency Infrared Lamp, increase heating efficiency 30%-50%.

b.Each layer of the lamp is separately controlled, with an assistant ruler on a machine.

c.Intelligent temperature control system.

Temperature detector feedback to PLC automatically, PLC makes an accurate judgment and then controls circulation air in the oven. It leads to constant temperature in Oven, free from voltage fluctuations and ambient temperature. It works when large ambient temperature difference (-28~45ºC).

d.Preform self-rotation System, ensure every side of every preform is heated evenly, which ensures the quality of the blown bottle. (thickness up to 4.5mm)

e.Neck Cooling in Oven.

Preform Necks are cooled by recycling water, which avoids neck deformation.

Product Parameter

| Items | #colspan# | Model |

| Mold Spec | Clamping stroke (mm) | 125 |

| Mold Spec | Stretching stroke (mm) | 240 |

| Mold Spec | Bottom stroke (mm) | 30 |

| Mold Spec | Cavity pitch (mm) | 114.3 |

| Mold Spec | Number of cavities (cavities ) | 6 |

| Container Spec | Max. volume, ctr (L) | 2 |

| Container Spec | Neck diameter (mm) | 18-38 |

| Container Spec | Max.diameter, ctr (mm) | 114.3 |

| Container Spec | Max. height, ctr (mm) | 320 |

| Power Spec | Total power (KW) | 130 |

| Power Spec | Heating Power (KW) | 120 |

| Air Compressor Spec | Blowing pressure (kg/cm²) | 28-35 |

| Air Compressor Spec | High-pressure air consumption (m³/min) | 3.6 |

| Water Chilling Spec | Operating pressure (kg/cm²) | ≥6 |

| Water Chilling Spec | Temperature range (℃) | 5~20 |

| Water Chilling Spec | Refrigerating capacity (kcal/hr) | 15000 |

| Water Chilling Spec | Flow Rate (m³/h) | 4.1 |

| Water Cooling Spec | Operating pressure (kg/cm²) | ≥4 |

| Water Cooling Spec | Temperature range (℃) | ≤30 |

| Water Cooling Spec | Flow Rate (m³/h) | 4.8 |

| Main Machine Spec | Size(L*W*H) (mm) | 5200*1790*2110 |

| Main Machine Spec | Weight (kg) | 7500 |