Juice Filling Machine

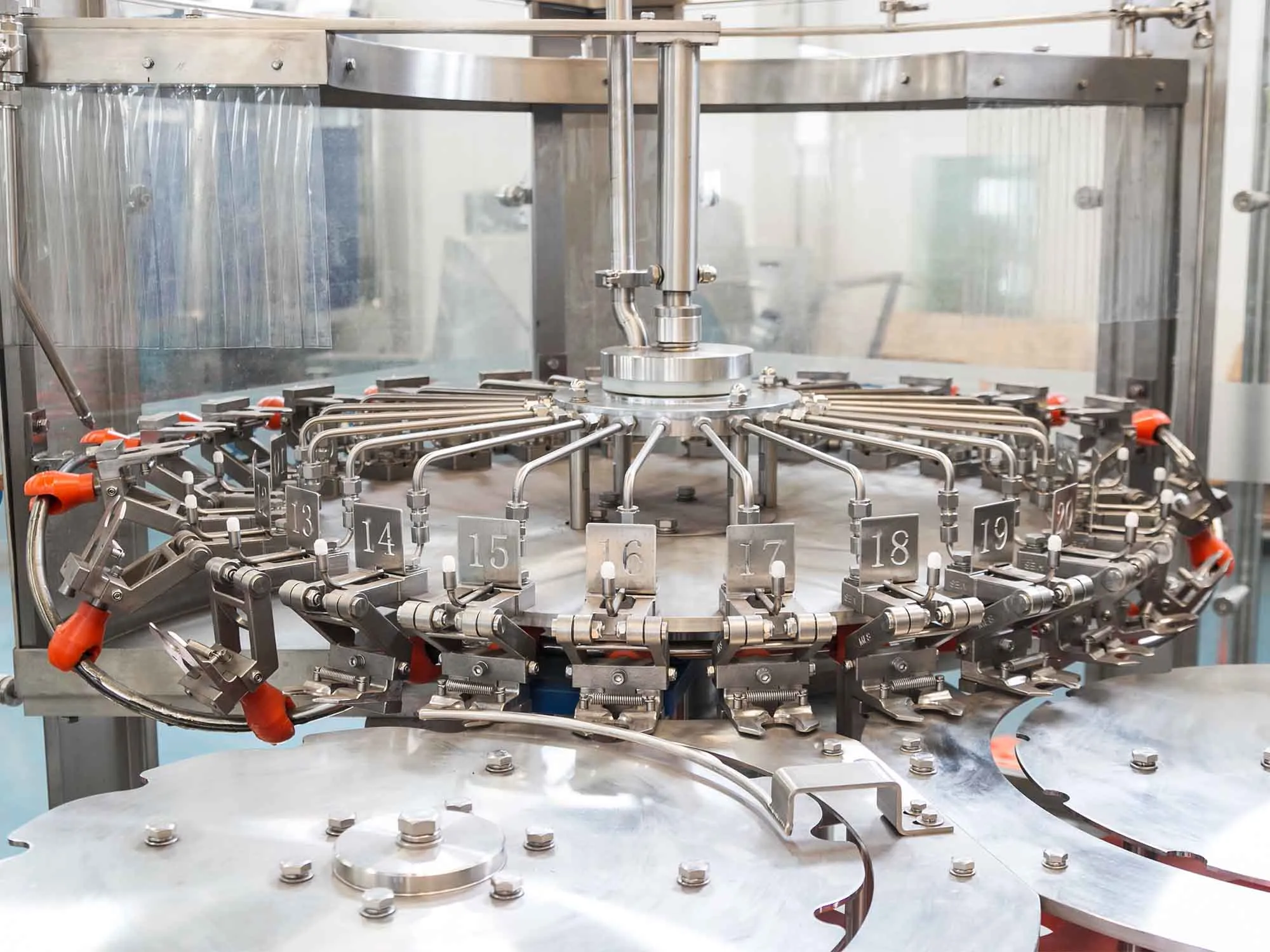

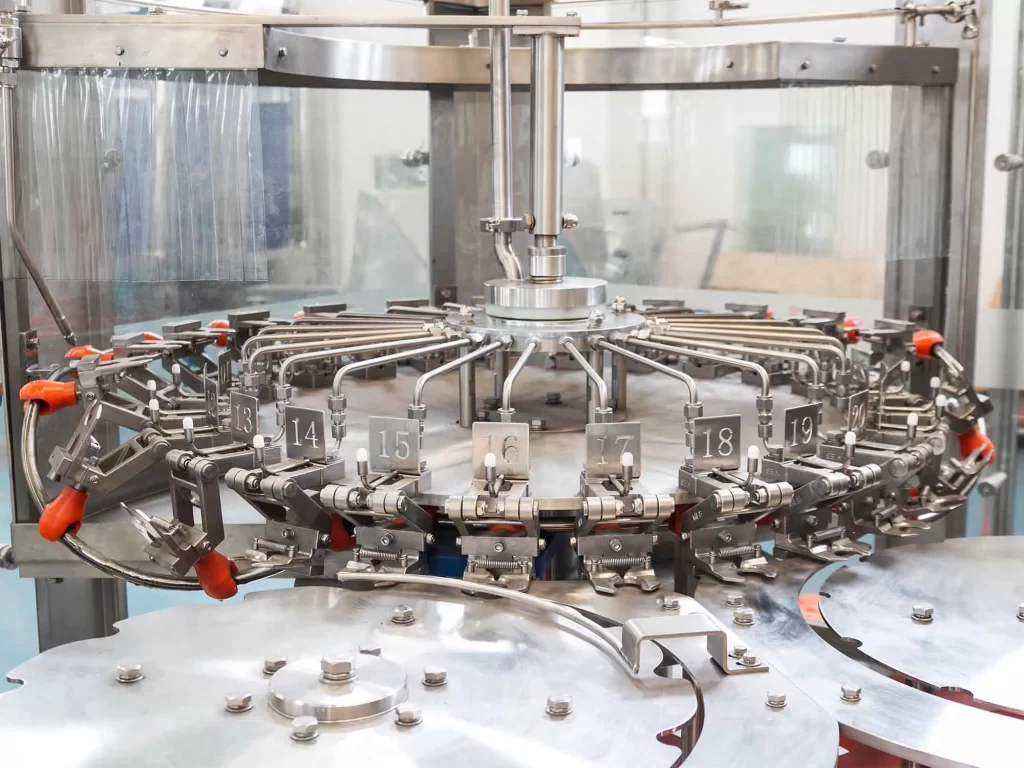

Fruit Juice Washing Filling Capping Machine

This series of equipment is used for hot filling production of tea drinks, fruit juice drinks and other products. This series is a combination of sterilization, filling and sealing. The design is scientific and reasonable, so operate is simple. It is the preferred equipment for hot-filling drinks.

Main Features

(1), The equipment is featured by compact construction, perfect controlled system, convenient operation, and high automatic level.

(2), It only needs to change the star-style wheel of spiral cover an arch board to change different bottles,

(3), The spare parts connected with the material are made of stainless steel, non-process dead-angle, easily cleaned.

(4), It adopts a high-speed filling valve, accurate liquid level, and non-liquid damage, to ensure filling industrial art.

(5), the Sealing cap is an adopted magnetic force-torque device, to ensure the sealing quality, and not to damage the cap.

(6), It adopts high efficient arranging cap system, which is characteristic with complete self-control and safety device.

(7), It’s equipped with a perfect over-load protecting device, which can protect effectively the equipment and operator.

(8), The controlling system is featured by producing speed control, missing cap detects, auto stop when bottles are stuck, production accounted.

(9), Main electric and pneumatic components are imported world-famous brands.

(10), The machine is adopted advanced touch screen control; human-machine dialogue operation is workable.

Washing Part

1. Adopting the direct connection technology between the air duct and the bottle feeding wheel, the bottle feeding screw and conveyor chain are eliminated, and the bottle shape is simple and easy to change.

2.Bottle transmission adopts the bottleneck clamping technology throughout the whole process. Changing the bottle shape does not need to adjust the height of the equipment. It only needs to replace the arc guide plate, dial wheel and other nylon parts related to the bottle diameter.

3. The high-speed line adopts bottle clamp transmission technology, the bottle shape changes more freely, and the internal working surface of the unit is more concise.

Filling Part

1. The three-in-one unit completes the three processes of bottle washing, filling and capping at one time, with little bottle wear, accurate and stable transmission, and convenient bottle type replacement.

2. The specially designed all-stainless steel bottle washer bottle clamp is sturdy and durable, and does not touch the threaded part of the bottle mouth to avoid secondary pollution of the bottle mouth.

3. High-speed and large-flow gravity filling valve, fast filling speed, accurate liquid level without liquid loss.

Capping Part

1. All parts in contact with liquid are made of high-quality stainless steel materials or food-grade engineering plastics, which meet the national food hygiene standards.

2. The bottle bottom support plate of the bottle output wheel adopts a spiral descending method, and the height of the bottle conveyor chain is not required to change the bottle shape.

Product Parameter

| Model | Machine name | Production capacity | Power (kW) | Low-pressure air consumption 0.8MPa (Nm³/min) | Application bottle type and range |

|---|---|---|---|---|---|

| DXGF14-12-5 | CSD filling machine | 2000BPH (500ml) | 2.25 | 0.8 | 350ml-1500ml (PET bottle) |

| DXGF18-18-6 | CSD filling machine | 4500BPH (500ml) | 2.75 | 0.8 | |

| DXGF24-24-6 | CSD filling machine | 8000BPH (500ml) | 3.35 | 0.8 | |

| DXGF32-32-8 | CSD filling machine | 12000BPH (500ml) | 5.27 | 0.9 | |

| DXGF40-40-10 | CSD filling machine | 14000BPH (500ml) | 5.87 | 1.2 | |

| DXGF50-50-12 | CSD filling machine | 17000BPH (500ml) | 9.25 | 1.2 | |

| DXGF60-60-15 | CSD filling machine | 20000BPH (500ml) | 12.2 | 1.2 | |

| DXGF72-72-18 | CSD filling machine | 26000BPH (500ml) | 15 | 1.2 | |

| BDXGF8-8-3 | CSD filling machine | 1000BPH (500ml) | 3 | 0.5 | 350ml-1500ml (Glass bottle) |

| BDXGF18-18-6 | CSD filling machine | 4500BPH (500ml) | 5.27 | 0.6 | |

| BDXGF24-24-8 | CSD filling machine | 8000BPH (500ml) | 5.27 | 0.8 | |

| BDXGF32-32-10 | CSD filling machine | 12000BPH (500ml) | 5.87 | 1.2 | |

| BDXGF40-40-12 | CSD filling machine | 14000BPH (500ml) | 5.87 | 1.2 | |

| BDXGF50-50-15 | CSD filling machine | 17000BPH (500ml) | 6.87 | 1.3 | |

| BDXGF60-60-15 | CSD filling machine | 20000BPH (500ml) | 7.67 | 1.3 | |

| BDXGF72-72-18 | CSD filling machine | 26000BPH (500ml) | 9.57 | 1.3 |