Carbonated Soft Drink Filling Machine

Glass Bottle Carbonated Soft Drinks Bottling Machine

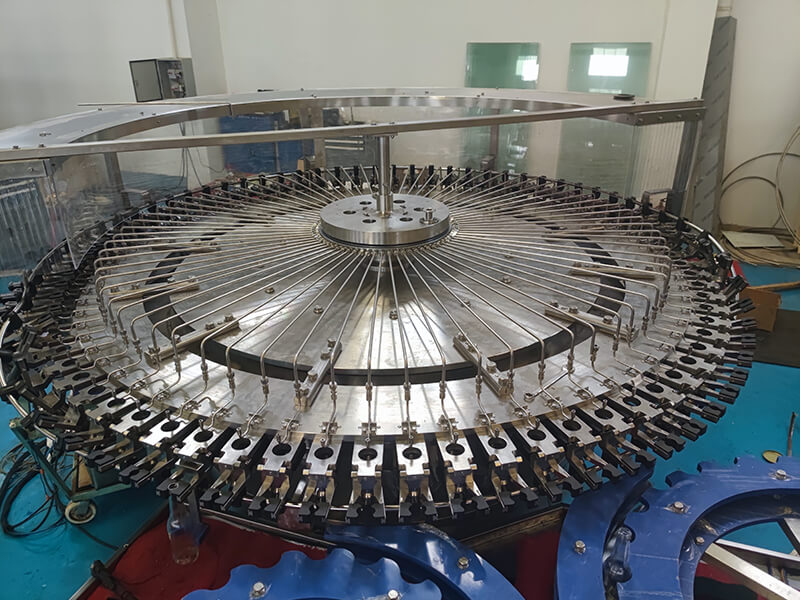

DXGF series isobaric filling machine is a 3-in-1 filling machine that combines rinsing, filling capping in one machine. The equipment is innovated and developed based on the introduction, digestion, and absorption of foreign advanced technology and according to the gas-bearing beverage filling process requirements, It is mainly used for soft drinks, cola, sparkling wine, mineral water, etc. The machine has a reasonable structure, safe, reliable, easy to maintain and it is the ideal equipment for a beverage filling factory.

Main Features

1. Compact structure, beautiful appearance, easy operation, high automation, low labor intensity.

2. Bottles transmission adopts bottlenecks clamping technology, no need to adjust the equipment height when changing bottle volume, simply replace the guide plate, thumbwheel that is related to the bottle diameter and mouth.

3. The parts that direct contact with the product are made of SUS 316L stainless steel and have no technology corner pockets

4. Valve opening device is driven by the cylinder; open the valve in time according to the signal, movements are accurate and reliable.

5. High-speed high-volume, high precision filling valve, filling fast, accurate, and non-liquid fluid loss.

6. Using deflection regulating valve, continuous control of fluid materials flow, so that hydraulic cylinder to maintain a smaller level fluctuations, to ensure filling accuracy.

7. Equipped with CIP circuit and control procedures, equipment is cleaned in place.

8. Capping head adopts a constant magnetic torque device to ensure the seal of quality, and will not damage caps.

9. Efficient use of the cap sorting system, with a perfect cap lacking a protective device.

10. Bottle-outlet thumb wheel adopts downward spiral approach, when changing bottle volume, no need to adjust conveyor height.

11. With a complete overload protection device, which can effectively protect the equipment and the operator’s safety.

12. Using touch-screen operation can realize man-machine dialogue, equipment operation status is very clear.

13. Main electrical components (touch screen, PLC, inverter, etc.) are imported brand-name products, Omron, Mitsubishi, Schneider, etc

14. Pneumatic system components are used in well-known brand-name products, SMC, or FESTO, etc

Rinsing Part

Direct connection to pure water system. The spring-loaded flushing pliers can automatically turn the empty bottle 180° with the track to flush the inside of the bottle. The flushing nozzle of the machine adopts quincunx shaped multi holes to flush the included angles of the bottle bottom fully, with high flushing efficiency.Filling Part

1.304/316 Stainless steel high precision filling nozzle 2. Filling volume adjustable in fine rank, same liquid level after filling 3. 304/316 stainless steel filling pump The filling machine adopts Italian technology, gravity low vacuum filling principle and secondary valve opening technology, so as to ensure the requirements of full liquid level filling process.Capping Part

1. Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping 2. All 304/316 stainless steel construction 3. No bottle no capping 4.Automatic stop when lack of bottle 5.Capping effect is stable and reliable ,defective rate ≤0.2%.Product Parameter

- The Filler is available to carry out the CIP (Clean-in-Place).

- The liquid level in filling tank is controlled by the float level switch.

- The filling temperature can be read, set and monitored by HMI (Touch Screen).

- Automatic stop feeding if low liquid level in filling tank.

- Automatic stop feeding if the liquid is below the filling temperature.

- All parts in contact with liquid are made of SUS304 stainless steel.

- Lube-free and maintenance saving Filler Lower Lifters.

- Motorized height adjustment for the seaming head.

- Equipped with Frequency Inverter for variable speed control.

- Automatic Centralized Lubrication System for the Filler and Seamer.

- All cams of Seamer are made by hardening and track fine grinding.

- Titanium Nitride (TiN) coating HORYANG® Seaming Rolls and Chucks.

- Seaming Rolls can be simply adjusted by the worm screws.

- Automatic No Can No Cover detection and safety protection system.

- Entire seaming area and work platform are made of SUS304 stainless steel.

- Automatic lubrication for bottom drive gears of the Seamer.

- SUS304 stainless steel guarding enclosure & tempered glass windows.

- Pneumatic Lid Gapper reducing the heavy weight of lid stack.

- Undercover CO2 and Steam Injection System. (Optional)

- Automatic WIP (Wash-In-Place) System. (Optional)

- Automatic Oil Circulation and Filtration System for bearings, gears and cams. (Optional)

- Motorized height adjustment for the Filler. (Optional)

| Model | Machine name | Production capacity | Power (kW) | Low-pressure air consumption 0.8MPa (Nm³/min) | Application bottle type and range |

|---|---|---|---|---|---|

| DXGF14-12-5 | CSD filling machine | 2000BPH (500ml) | 2.25 | 0.8 | 350ml-1500ml (PET bottle) |

| DXGF18-18-6 | CSD filling machine | 4500BPH (500ml) | 2.75 | 0.8 | |

| DXGF24-24-6 | CSD filling machine | 8000BPH (500ml) | 3.35 | 0.8 | |

| DXGF32-32-8 | CSD filling machine | 12000BPH (500ml) | 5.27 | 0.9 | |

| DXGF40-40-10 | CSD filling machine | 14000BPH (500ml) | 5.87 | 1.2 | |

| DXGF50-50-12 | CSD filling machine | 17000BPH (500ml) | 9.25 | 1.2 | |

| DXGF60-60-15 | CSD filling machine | 20000BPH (500ml) | 12.2 | 1.2 | |

| DXGF72-72-18 | CSD filling machine | 26000BPH (500ml) | 15 | 1.2 | |

| BDXGF8-8-3 | CSD filling machine | 1000BPH (500ml) | 3 | 0.5 | 350ml-1500ml (Glass bottle) |

| BDXGF18-18-6 | CSD filling machine | 4500BPH (500ml) | 5.27 | 0.6 | |

| BDXGF24-24-8 | CSD filling machine | 8000BPH (500ml) | 5.27 | 0.8 | |

| BDXGF32-32-10 | CSD filling machine | 12000BPH (500ml) | 5.87 | 1.2 | |

| BDXGF40-40-12 | CSD filling machine | 14000BPH (500ml) | 5.87 | 1.2 | |

| BDXGF50-50-15 | CSD filling machine | 17000BPH (500ml) | 6.87 | 1.3 | |

| BDXGF60-60-15 | CSD filling machine | 20000BPH (500ml) | 7.67 | 1.3 | |

| BDXGF72-72-18 | CSD filling machine | 26000BPH (500ml) | 9.57 | 1.3 |