Can Filling Machine

Can Filling Sealing Machine

Filling and seaming capacity of 600 – 800 cans per minute in maximum. It is suitable for filling with low viscosity liquids in aluminum and steel beverage cans, such as juice, coffee, tea, coconut juice, walnut milk and sesame seed paste, etc. The Filler is driven by the Seamer for synchronized operation. The new designed filling machine integrates the multiple CIP functions, lube-free filling lifter and motorized working height adjustment, etc.

Main Features

1. The Filler is available to carry out the CIP (Clean-in-Place).

2. The liquid level in filling tank is controlled by the float level switch.

3. The filling temperature can be read, set and monitored by HMI (Touch Screen).

4. Automatic stop feeding if low liquid level in filling 5. Automatic stop feeding if the liquid is below the filling temperature.

6. All parts in contact with liquid are made of SUS304 stainless steel.

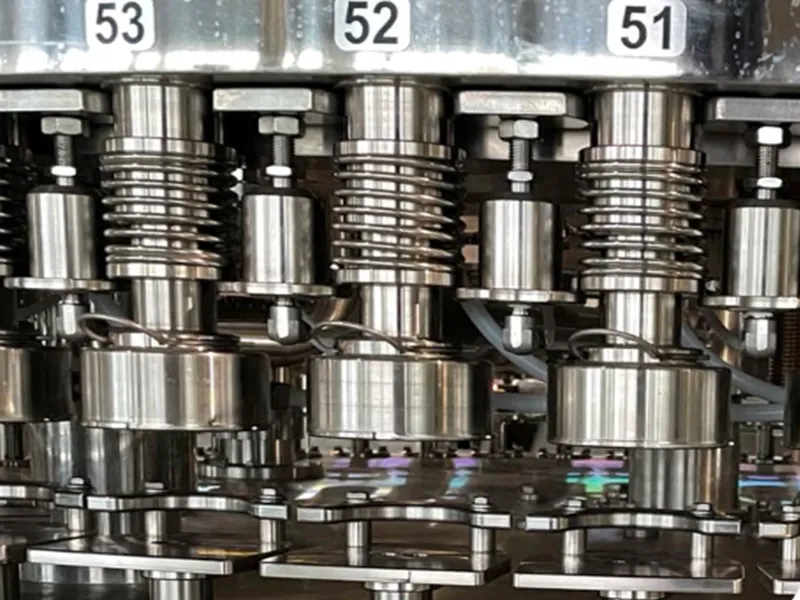

7. Lube-free and maintenance saving Filler Lower Lifters.

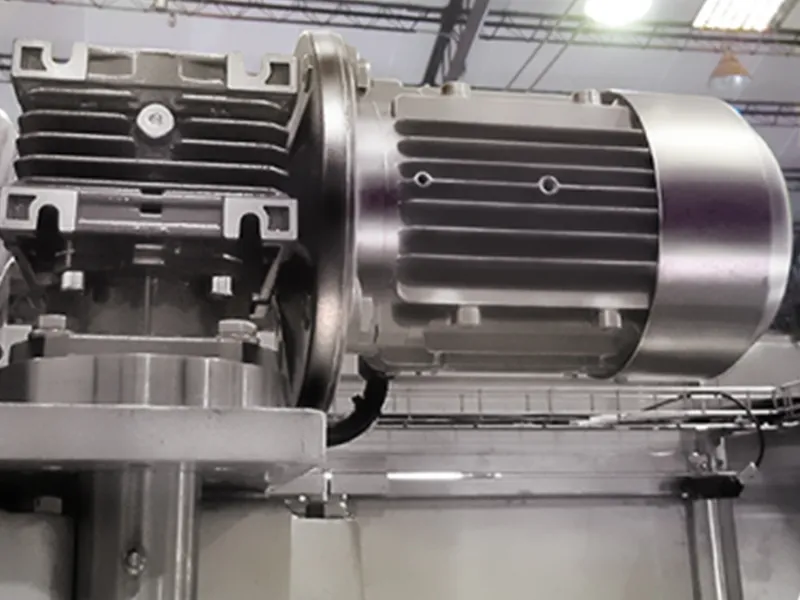

8. Motorized height adjustment for the seaming head.

9. Equipped with Frequency Inverter for variable speed control.

10. Automatic Centralized Lubrication System for the Filler and Seamer.

11. All cams of Seamer are made by hardening and track fine grinding.

2. The liquid level in filling tank is controlled by the float level switch.

3. The filling temperature can be read, set and monitored by HMI (Touch Screen).

4. Automatic stop feeding if low liquid level in filling 5. Automatic stop feeding if the liquid is below the filling temperature.

6. All parts in contact with liquid are made of SUS304 stainless steel.

7. Lube-free and maintenance saving Filler Lower Lifters.

8. Motorized height adjustment for the seaming head.

9. Equipped with Frequency Inverter for variable speed control.

10. Automatic Centralized Lubrication System for the Filler and Seamer.

11. All cams of Seamer are made by hardening and track fine grinding.

1. Titanium Nitride (TiN) coating HORYANG® Seaming Rolls and Chucks.

2. Seaming Rolls can be simply adjusted by the worm screws.

3. Automatic No Can No Cover detection and safety protection system.

4. Entire seaming area and work platform are made of SUS304 stainless steel.

5. Automatic lubrication for bottom drive gears of the Seamer.

6. SUS304 stainless steel guarding enclosure & tempered glass windows.

7. Pneumatic Lid Gapper reducing the heavy weight of lid stack.

8. Undercover CO2 and Steam Injection System. (Optional)

9. Automatic WIP (Wash-In-Place) System. (Optional)

10. Automatic Oil Circulation and Filtration System for bearings, gears and cams. (Optional)

11. Motorized height adjustment for the Filler. (Optional)

2. Seaming Rolls can be simply adjusted by the worm screws.

3. Automatic No Can No Cover detection and safety protection system.

4. Entire seaming area and work platform are made of SUS304 stainless steel.

5. Automatic lubrication for bottom drive gears of the Seamer.

6. SUS304 stainless steel guarding enclosure & tempered glass windows.

7. Pneumatic Lid Gapper reducing the heavy weight of lid stack.

8. Undercover CO2 and Steam Injection System. (Optional)

9. Automatic WIP (Wash-In-Place) System. (Optional)

10. Automatic Oil Circulation and Filtration System for bearings, gears and cams. (Optional)

11. Motorized height adjustment for the Filler. (Optional)

Product Parameter

| Model | F40A / S60 | F40B / S60 | F56A / S80 | F56B / S80 |

| Max. Capacity | 600 cpm | 600 cpm | 800 cpm | 800 cpm |

| Horsepower | 15 HP (11.2KW) | 15 HP (11.2KW) | 15 HP (11.2KW) | 15 HP (11.2KW) |

| Can Discharge Height | 1200 mm | 1200 mm | 1200 mm | 1200 mm |

| Number of Heads | 40H / 6H | 40H / 6H | 56H / 8H | 56H / 8H |

| Filling Tank Volumn | 560 L | 300 L | 560 L | 360 L |

| Dimensions (LxWxH) | 7280 x 3800 x 3500 mm | 7280 x 3800 x 2785 mm | 7280 x 3800 x 3500 mm | 7280 x 3800 x 2785 mm |

| Power Consumption | 20 KW | 20 KW | 20 KW | 20 KW |

| Can Feed Height | 1200 mm | 1200 mm | 1200 mm | 1200 mm |

| Can Height Range | 70 – 180 mm | 70 – 180 mm | 70 – 180 mm | 70 – 180 mm |

| Filling Tank Diameter | 1474 mm | 1884 mm | 1474 mm | 2106 mm |

| Gross Weight (Approx.) | 8350 / 3670 kgs | 8510 / 3670 kgs | 9060 / 3770 kgs | 9220 / 3770 kgs |

| Net Weight (Approx.) | 6450 / 3090 kgs | 6330 / 3090 kgs | 7650 / 3190 kgs | 7510 / 3090 kgs |

| Can Diameter Range | 202 – 401D (52-99mm) | 202 – 401D (52-99mm) | 202 – 301D (52-74mm) | 202 – 301D (52-74mm) |